Mojow President, Owen Kinch, is a multi-talented entrepreneur with a varied background that lends itself well to co-leading the CAAIN-funded Autonomous Tractor Kit for Enabling Autonomous Farm Implement Operation. A grain farmer who has always worked off farm to feed his penchant for technological innovation, he spent seven years in SeedMaster’s R&D department, before becoming the first employee of the company’s autonomous vehicle spinoff, DOT Technology Corp. While there, he met his friend and eventual Mojow co-founder, Mojtaba (Moji) Hedayatpour, a gifted systems architect and software developer.

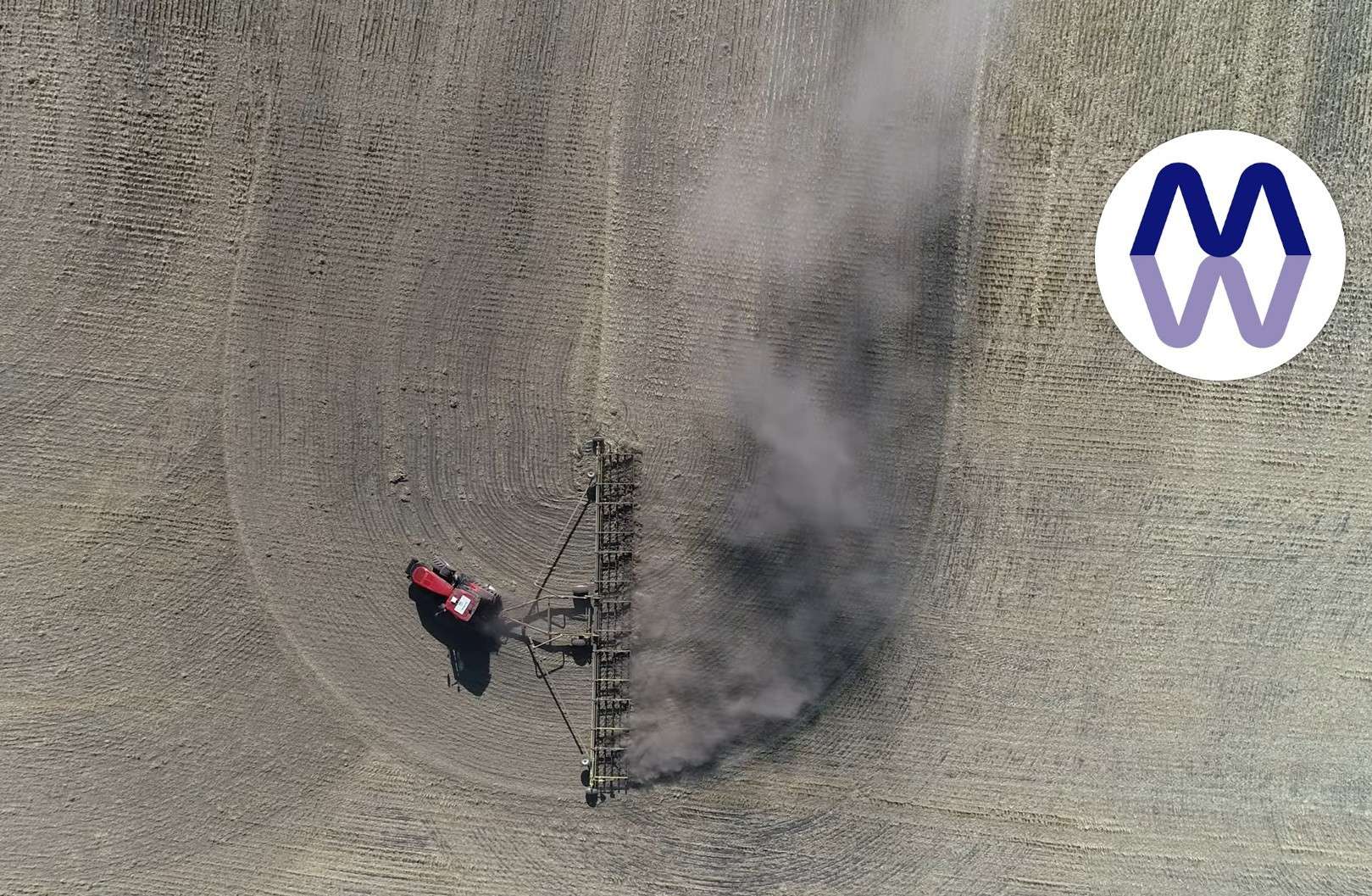

While still at DOT, he farmed his own land year-after-year with the company’s autonomous platform, and the experience provided unique insight into the challenges that slow adoption of such innovation. When Owen left DOT and returned to his farming roots, he soon became frustrated with how much of his work still required manual labour. So, he sat down with other producers to better understand how technology might improve broad-acre farming. What emerged was eye-opening and led Moji and him to found Mojow in early 2020.

Autonomous agtech is widely viewed as a key to reducing the agri-food sector’s reliance on increasingly scarce labour. However, existing models generally depend on GPS-driven navigation controllers, which don’t deal well with unplanned obstacles. They therefore require the constant vigilance of a trained human operator, and do not meet the threshold for autonomy, which Oxford Languages defines as, “Freedom from external control or influence; independence.*”

“It’s relatively easy to develop machines that can drive up and down fields independently in straight lines,” Owen explains. “But that’s not the entire farming story. Three important bottlenecks or complex challenges must be addressed if agricultural machinery is to operate without human intervention. The first is driving the headland [untilled land at the ends of fields or near a fence – ed.] autonomously without prior mapping. Second, the equipment must navigate the roads between the fields. And the last big piece is the ability of the tractor to transition seamlessly from road to field using entrances. If it can do all that, a vehicle is truly autonomous.”

Owen goes on to note these three key elements are all part the single overarching advance in computer vision software that Mojow is tackling. “Our customers’ equipment should drive itself from the yard to the road, access any fields and roads necessary, and return to its starting point when the job is done.”

So how does it work? The Mojow system employs a series of stereo cameras installed around the vehicle to create a 360-degree unobstructed view of its environment. Everything runs through a proprietary controller called EYEBOX™, which automatically manages frame rates of anywhere between 10 and 30 images per second, depending on the vehicle speed and required job function.

EYEBOX™ is a small, rugged, economical sensor suite outfitted with multiple cameras, a GPS, and a powerful computer that processes data in real time. The system collects images automatically, passing them through a deep neural network that classifies each pixel to create (or update) a digital representation of the entire farming entity (field boundaries and entrances, roads, etc.). This digital twin, or map, of a farm’s physical attributes serves as the foundation (or primary input) of the autonomous navigation controller—the “brain” that guides the machinery and makes it truly autonomous. The continuous intake of real-time image data from the peripherals of the tractor assures a high level of relative position accuracy between the vehicle and any physical object encountered within its working environment.

As part of the CAAIN-funded project deliverables, the team is addressing:

EYEBOX™ is designed to operate ISO 11783-certified farm implements such as air seeders, sprayers, and fertilizer spreaders. However, Mojow intends to start with land rolling and heavy harrowing, thereby proving its concept before adding tools that apply product. Designed for flexibility, the platform can convert conventional tractors into autonomous vehicles or be integrated into OEM machinery to enhance functionality. Either way, when fully functional, it will reduce a farm’s production costs and reliance on unskilled labour, increasing profitability and productivity.

The support Mojow has received from CAAIN has helped fast-track the development process so that in less than four years, the company is on the verge of introducing a commercially viable product. “We’re headquartered in Edmonton mainly to take advantage of the gifted computer-vision, AI, and machine-learning professionals trained by the University of Alberta,” Owen notes. “But we wouldn’t have been able to hire so many of the top graduates without CAAIN funding. We’ve also benefited from your network thanks to Garson Law, the program manager assigned to our project. He connected us to a number of companies and individuals whose support has made a big difference. We really appreciate everything you guys have contributed to our success.”

* https://languages.oup.com/google-dictionary-en/

CAAIN Contribution

$682,028

Total Project Value

$2,225,680

Project Contact

Owen Kinch

Mojow Autonomous Solutions

owen@mojow.ai

Here are some videos of the system in action.