CAAIN is proud that several of our projects are led by companies whose CEOs and other senior leaders are women. EDI is an overused term but an underused concept. We support efforts to increase the number of women making decisions in Canada’s agri-food sector, so it was a pleasure to sit down with Olga Pawluczyk, MSc, MBA, Chief Executive Officer of P&P Optica, the lead partner of Using Automation, Data, and Insights to Improve Meat Quality and Safety, one of two initiatives selected through CAAIN’s 2002 Beef and Pork Primary Processing Automation and Robotics Program.

CAAIN: We’re so pleased to be supporting PPO’s meat quality project, but we’re puzzled. How does a company founded by a leading expert on the behaviour of light—basically we’re talking about spectroscopy—end up working in the agri-food sector?

Olga Pawluczyk: That’s a great question. The best way to answer is to describe the PPO journey.

Our co-founder, my father, Dr. Romek Pawluczyk, grew up and studied in Poland, developing an expertise in photonics and spectroscopy, and designing and creating, among other things, his country’s first hologram.

C: What are “photonics?”

OP: Photonics is the physical science of light waves.

C: Got it. Thanks. So how do you go from building a hologram to improving the quality of my ribeye?

OP: Dad emigrated to Canada in the early ‘80s, and co-founded P&P Optica in 1995. Originally, PPO was an optics and consulting operation. Romek designed the optics in our spectrometers, which to this day are considered the gold standard—they’re so superior to everything else on the market that one of our units is on the International Space Station.

C: That’s incredibly cool, but if anything, we’re getting further away from meat processing.

OP: Let’s keep going with the story. I have a master’s degree in medical biophysics from U of T, and in 2001, I finished my studies in medical imaging and joined PPO as Vice President of Development. I recognised the opportunity to commercialise my father’s technology and expand beyond the world of research and consulting. Our first foray was into the recycling industry. You can use light to conduct non-destructive materials testing, and our spectrometers were able to differentiate among different kinds of plastic, allowing recyclers to make sure they were accurately sorting the different containers and other items they received.

C: Fascinating. This is starting to make sense. CAAIN is supporting other projects that use light spectrum applications to provide agri-food analytics.

OP: Right. There are many uses for light waves. I became CEO in 2005, and guided PPO into the oil & gas sector, applying our technology to oil sands bitumen analysis. But in 2015, the oil and gas sector nosedived, and we needed to broaden our horizons. At about that time, we took a couple of calls from meat processors asking if PPO’s equipment could differentiate meat from fat, as well as detect material that shouldn’t be in the meat. That kind of analysis is analogous to finding globules of oil suspended in globules of other substances, so we took on the challenge and diversified.

C: What kind of material would be in meat that shouldn’t be there?

OP: Mainly different types of plastics and rubbers, but also other materials like cardboard and wood.

C: Plastic and rubber? In a meat plant?

OP: There’s plastic everywhere in a meat plant—for example, most meats are stored and transported in plastic liners. And rubber is used in personal protective equipment, cardboard is used to box the product, and there’s metal in the tools and equipment used in the plant. All these different materials can create tiny pieces of foreign matter that are virtually undetectable and can stick to the product at various stages of processing.

C: Add that to the list of things I did not know.

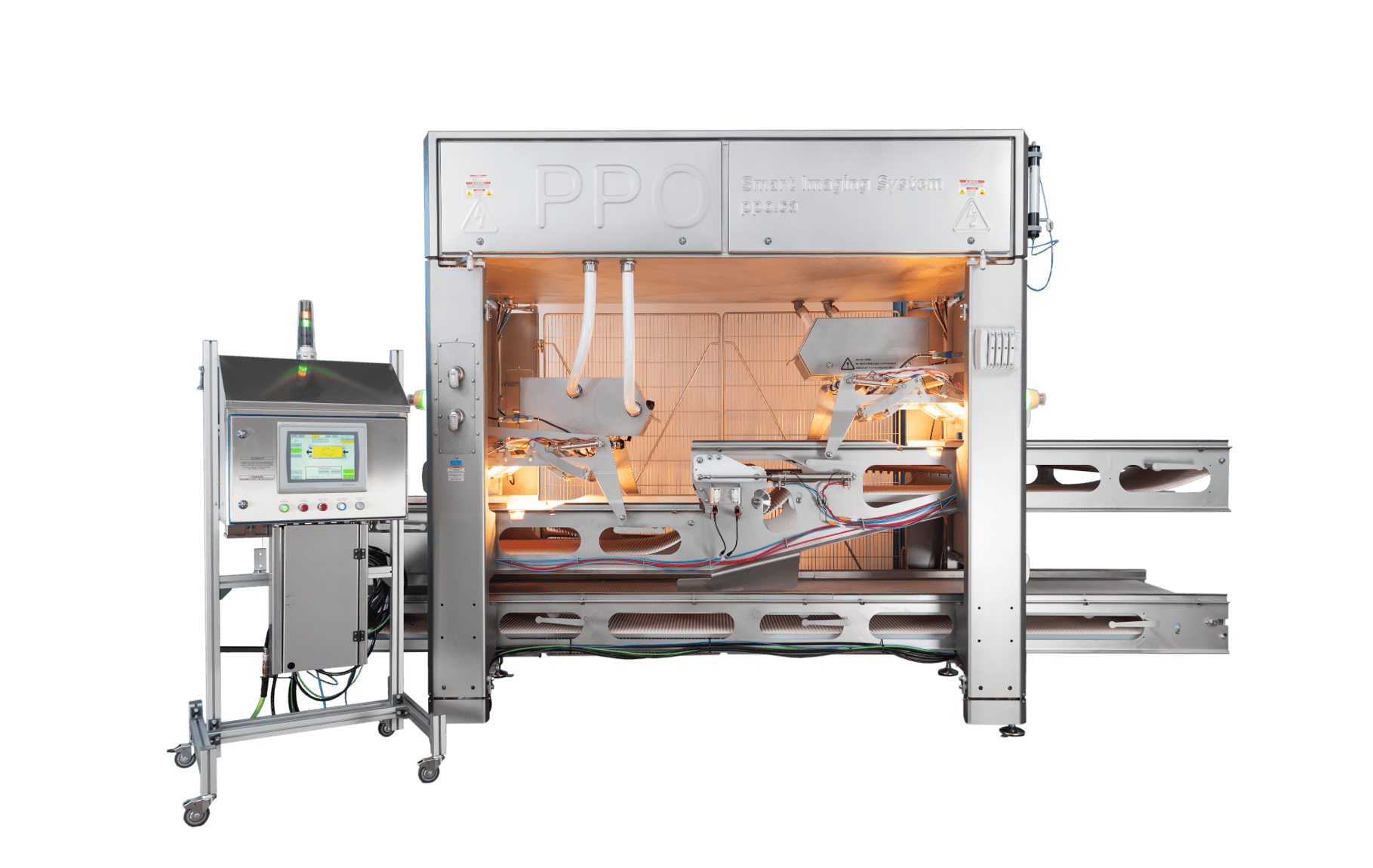

OP: That started us in the meat industry, and we’ve been there ever since. Today we use light waves generated by our system to provide real-time chemical analysis in processing plants. It’s very difficult to detect anomalies visually using a regular camera, particularly at line speed, but because we use spectroscopy along with a typical vision-based camera, our technology can “see” things the human eye can’t discern.

C: Wow. That’s amazing. AI must play a role, then.

OP: It does. Artificial intelligence and machine learning interpret the spectrometer’s readings. The process is entirely automated. People help to train the software, but no humans are involved in the actual inspection and analysis. We have almost 20 systems in place in pork and poultry operations across North America, and our clients report back that those facilities experience little to no contamination after inspection by our systems.

C: And this would be primary processing?

OP: And secondary as well as ready-to-eat plants. We are often deployed on the way out in primary processing facilities and on the way in to secondary processors, which pretty much eliminates the possibility of foreign substances finding their way to the consumer.

C: Very cool. Now given that you’ve been providing these kinds of services for several years, this obviously is not what we’re funding. What is the ISED-CAAIN support providing?

OP: Because we’re set up to “read” the chemical composition of the meat, we can also assess things such as fat, water, and protein content, as well as freshness. We can analyse and provide information on a range of quality metrics. Our project is focused on using the data we generate not only to inform processors and consumers, but also to tell farmers what their efforts are yielding. In other words, we’re reverse engineering for primary meat producers by helping them evaluate the effects of their on-farm practices. What’s more, we do this without damaging the meat. The data we provide can be used by farmers to compare their results to data they generate and collect regarding their operations, allowing them to adjust what they’re doing and thereby deliver the best quality animals to their customers, the primary processors. That’s the project CAAIN is funding, and we’re excited to see what will develop as we proceed.

C: Olga, this is amazing. You and your father have created something truly remarkable. Thank you so much for taking the time to explain PPO’s work.

OP: It’s my pleasure. Thanks for CAAIN’s support. It’s going a long way to helping us expand the use of this amazing technology in the market.

CAAIN Contribution

$2,973,651

Total Project Value

$9,514,562

Project Contact

Olga Pawluczyk

CEO

P&P Optica

olga@ppo.ca